|

Slurry systems, vacuum seperators are a few of the value added items that we make for the machines we support. If you have special request plese don't hesitate to call us 515-778-0895

|

|

| VS1 - Vacuum Seperator |

|

|

|

| CS1 - Vacuum Seperator |

|

|

Vacuum Seperators

A vacuum seperator is used to seperate out waste water and route it to the drain. These systems are used with polishers and grinders which use vacuum.

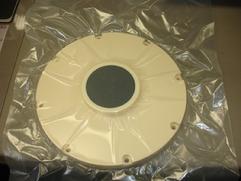

VS1 seperator

PLC Controlled and has the ability to communicate with a host. Alarms are configurable so that if a sensor goes out the system can run on a time basis. The VSI has the option of using water to flush the tanks to keep them clean depending on the medium. The tanks can also be removed easily.

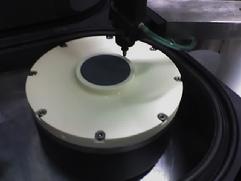

CS1 sperator uses a timer valve and runs continuely based on this time cycle. The system is simple but works well.

Both systems are built to run continuesly without failure.

|

|

|

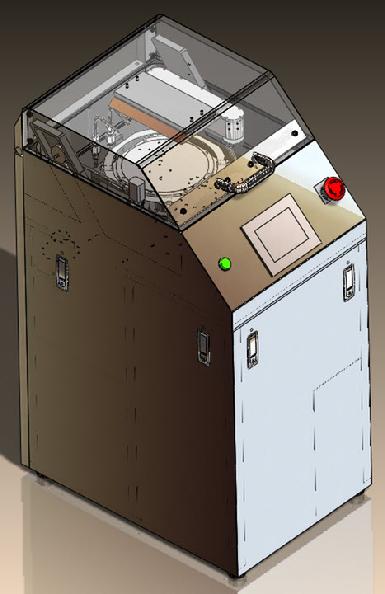

CS2 Vacuum Separator

Similar to the CS1 with larger capacity. The unit replaced the vacuum pump assembly on the Disco 82IF/8 backgrinder and can be used on other backgrinders or CMP systems.

· Tanks can be removed and cleaned.

· All tubing, fitting and valves coming in contact with fluid are Teflon.

· Enough volume to allow connection to multiple tools this is subject to the time setting unless PLC controlled.

PLC control is optional as well as I/O connections to connect to customer’s machine or host.

|

We have designed work chucks for different machines the following are a few of those chucks.

|

|

|

Strasbaugh 7AA Work Chucks

Strasbaugh 7AA standard vacuum chucks can be rebuilt. If you have a 7AA and would like your chucks rebuilt please contact us at 515-778-0895.

We also make new chucks for the 7AA. The universal chuck is for customers that are running multiple sizes and need to switch between them.

The New 7AA chuck is for individual size wafers and can be purchased in the following sizes:

· 3”

· 100mm

· 125mm

· 150mm

Special sizes can be made.

|

|

|

|

| Strasbaugh 7AF 3" Work Chuck |

|

|

Strasbaugh 7AF Work Chucks

The 7AF chuck is for individual size wafers and can be purchased in the following sizes:

· 3”

· 100mm

· 125mm

· 150mm

· 200mm

Special sizes can be made.

|

|

| 7AF 3" Work Chuck |

|

|

We design slurry systems to customer specifications.

|

|

| Portable CMP Slurry System |

|

| Portable CMP Slurry Tank

- 30 Gallon cone bottom or flat bottom tank.

- Mixer (variable speed) can be moved up/down and in/out.

- CPC PVDF fittings on both the tank connections as well as the I/O connections.

- Capacitance sensor for “Low Level Limit”.

- Capacitance sensor for "Leak Detection"

- I/O connections can be mounted on the sides or rear of the system.

- Slurry containment 13 gallons.

- Rear wheel lock.

- Peristallic Pump and diaphragm pump can both be installed on the system. As well as two peristallic pumps on the same system.

- Made to Order.

|

|

| Portable CMP Slurry System |

|

|

|

| Wafer Washer |

|

| Small Wafer washer

· PLC Control and HMI allowing storing of recipes.

· Megasonic nozzle either single or dual frequency.

· Brush arm.

· Multiple fluid nozzles.

· Different chucks are available for either wafers or tape frames.

· Servo controlled.

|

|