|

| Mitsunaga 3B |

|

|

Mitsunaga 3B Update and Recondition

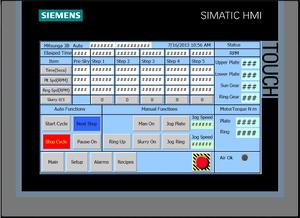

- New Siemens controls

- S7-1200 with

- 7" Comfort screen

- Manual functions (within the Auto Cycle Screen)

- Ring Up – The Ring must be in the up position to enable the motors. There is no up switch on the machine and the air has to be high enough to allow movement of the ring gear up and down. The ring gear button will turn green when it is enabled. The auto cycle will not start if the ring gear up solenoid is not on.

- Man On – This is Manual on button which when depressed turns on the plate and ring drive based on the Jog Speeds.

- Slurry On – Enables the slurry outlet.

- Jog Plate – Momentary button jogs the plate drive at the speed listed in the jog speed box. 0-80 rpm is the limit

- Jog Ring – Momentary button jogs the ring gear based on the Jog Speed I/O field. -80 to +80 are the limits.

- Jog Speed I/O fields – Allows entering the speed 0-80 rpm(plate) and -80 to +80 (Ring) the fields are green when the Manual functions are available. In Auto they will turn white.

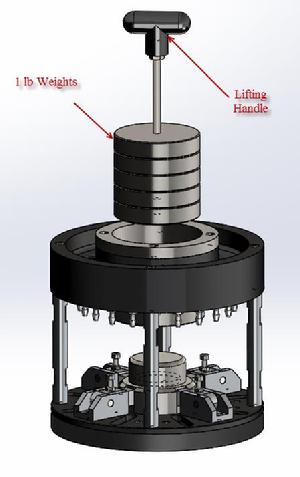

- DC motor which drove all the motion originally was replaced with two servo motors

- Ring Gear is driven seperately allowing rotation of the carriers in the opposite direction. Plate flatness can be maintained.

- Downforce is controlled by weigts which can be added to or removed.

- Boom assembly is also available. Provides the following added features:

- Sony Probe intergration

- The Sony probe is read via the internal network and is display on the HMI.

- It can be enabled per step and the value save in the recipe.

- Plate wear is also tracked.

- Downforce is controlled via two cylinders.

- Downforce is controlled per step in the recipe.

|

|

| 3B Auto Cycle |

|

|

|

| 3B Upper Plate |

|

|

|

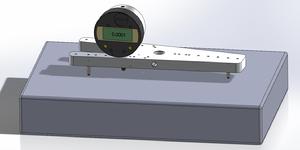

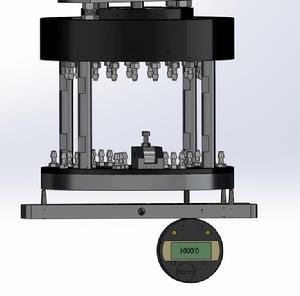

| 3B Plate Flatness Gauge |

|

|

Mitsunaga 3B Flatness gauge

The flatness gauge kit for the Mitsunaga 3B contains the following components:

- 900087-3B – The base which the indicator and other components are mounted it contains 4-48 thread holes to allow moving the tips to various locations to check the flatness on different objects.

- 900087-3B-1 – Bronze sleeve which has been modified to allow the set screw to cinch the indicator in place.

- 900087-3B-2 – Tips

- 900087-3B-3 – 8-32 set screw

- 900087-3B-4 – Granite Flat

- 900087-3B-5 – Indicator

- Accuracy 0.00012”

- Resolution 0.00005”

|

|

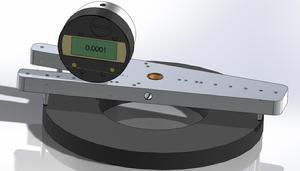

| 3B Flatness gauge Lower Plate |

|

|

|

| 3B Flatness Gauge Upper Plate |

|

|

|